Crome Services

From design starting from a blank page or a set of specifications to manufacturing, covering the entire development process, including prototyping, risk assessment, and qualification.

The Steps of Our Collaboration

Supporting you with your challenges from design to production.

We also provide guidance to internal teams.

Submission of Specifications

Understand your needs and expectations, define a budget range, and identify your timelines and project context.

Technical and Financial Guidance and Responses

After analysis, propose several solutions, both technical and ergonomic.

Define the actual budget.

Design and Development

Once manufacturing is complete, either ship or deliver it.

Ensure follow-up.

Testing and Manufacturing

Once manufacturing is completed, either ship or deliver it.

Carry out follow-up.

Design & Modeling

Based on a set of specifications, even if incomplete, Crome will leverage its resources and expertise in the design and definition of your equipment, whether onboard or simulated, according to your needs.

Whether for new onboard equipment, training simulators, or the modification and retrofit of existing systems, we can apply our wide range of technical skills to provide you with reliable and high-performance solutions.

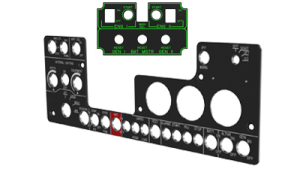

Our mechanical, electronic, and optical studies are carried out using CAD software recognized in the aeronautics industry, ensuring precision and compliance. We can also produce functional prototypes through 3D printing or other production methods, allowing you to quickly visualize, test, and integrate your project.

Crome offers a complete approach: customized design, 3D modeling, and rapid prototyping for the integration and testing of your onboard solutions.

DEVELOPMENT & MANUFACTURING

While adhering to your development phases and milestones, Crome will provide all the technical documentation required for the validation of your projects.

Crome can handle the procurement of specific components, working with a carefully selected network of mainly local suppliers, while remaining autonomous and responsive through the integration of most processes and resources.

Machining, painting, engraving, marking, assembly, wiring, electrical, dimensional, or photometric testing—our machinery and special processes cover the majority of technical and strategic needs, ensuring complete production traceability.

Our fully integrated approach, driven by a powerful ERP/MRP system, ensures effective control of costs, lead times, and above all, quality.

TESTING & INSPECTIONS

Crome is equipped with a comprehensive inspection facility to verify completed equipment under optimal conditions.

Whether dimensional, electrical, or optical, our regularly monitored and calibrated measurement tools ensure the quality and safety of your equipment.

If needed, we can also design, program, and build test benches to check more complex equipment or systems combining multiple techniques and technologies.

We use measurement, inspection, and testing tools from leading, industry-recognized manufacturers to guarantee quality and repeatability.

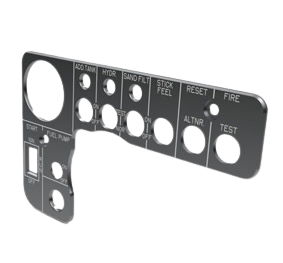

Retrofit - Modification

Aircraft are designed to last for several decades, but technologies continuously evolve and need to be updated to ensure pilot safety and mission efficiency.

Crome can propose and develop technical solutions to modify or replace existing equipment, extending its service life or improving user comfort, while complying with international standards and regulations (night vision capability, lighting technology upgrades, etc.).

OUR ACHIEVEMENTS

Discover examples of custom-made projects.

MAJOR PLAYERS IN AERONAUTICS AND DEFENSE ALREADY TRUST US